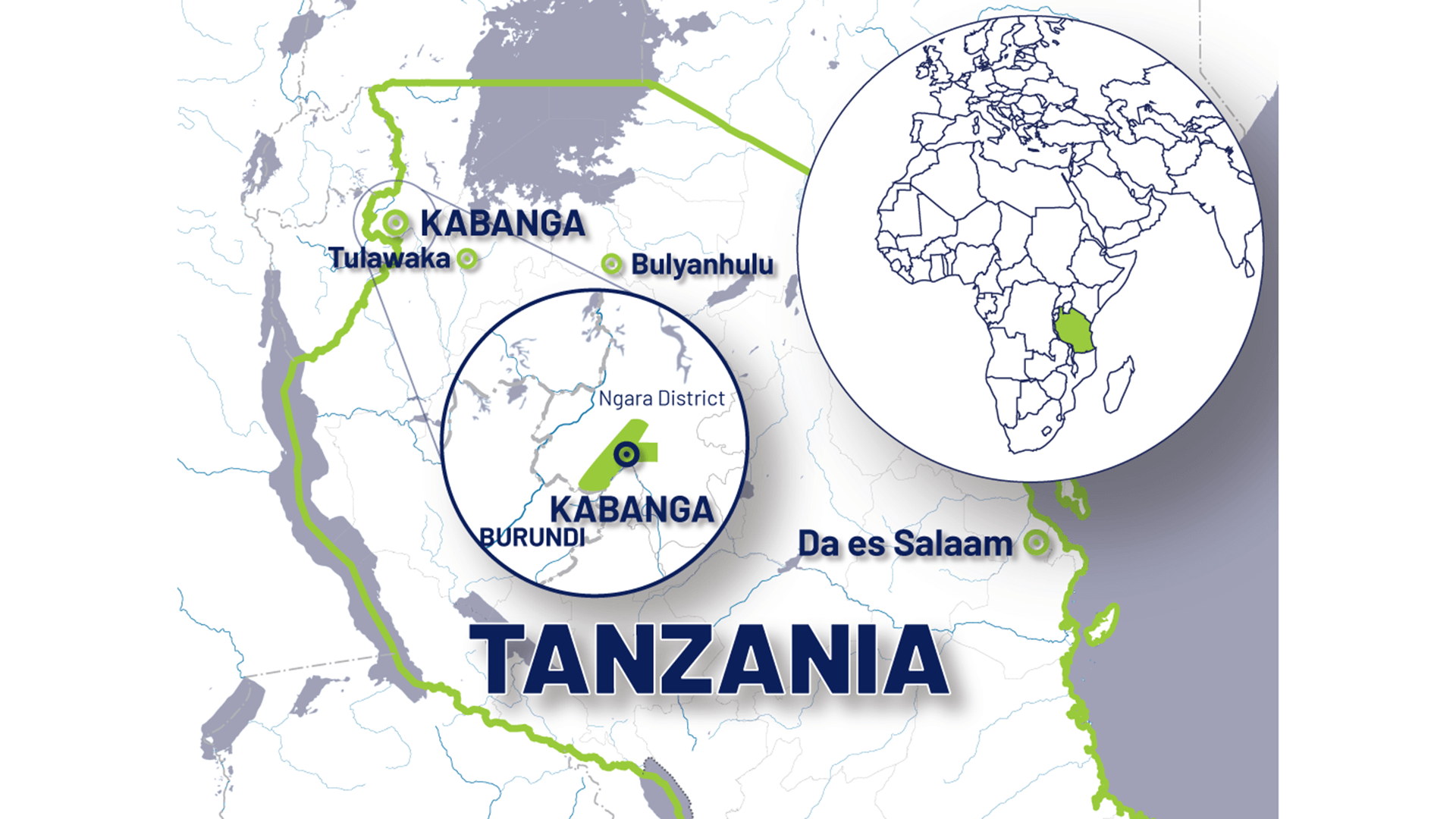

Tembo Nickel Corporation, a subsidiary of UK-based mining firm Kabanga Nickel Limited is finalizing the feasibility study for its nickel deposits discovered in Kabanga ward north-west of Tanzania in Ngara district, Kagera region near Burundian border two years ago.

Located in the north-west of Tanzania, the Kabanga nickel project hosts the world’s largest development-ready nickel sulphide deposit, unmatched in scale and grade, with a mineral resource of some 2 million tonnes1 of contained nickel equivalent

Tanzania and UK-based mining firm Kabanga Nickel Limited signed a framework agreement in January 2021 to jointly develop the Kabanga nickel project formerly owned by Barrick Gold and Glencore.

Under the new accord, the government of Tanzania would own a 16 per cent undiluted free-carried interest in the nickel project through a new joint venture company, Tembo Nickel Corporation, 84 per cent owned by Kabanga Nickel.

The signed binding Framework Agreement had a condition that later finishes the feasibility studies first prior to start mining activities.

Reliable sources from within the company say that, 80 per cent of the evaluation work has already been done for the project’s buffer zone.

The affected families are currently awaiting compensation according in accordance with the law in order to pave the way for mining activities slated for 2025.

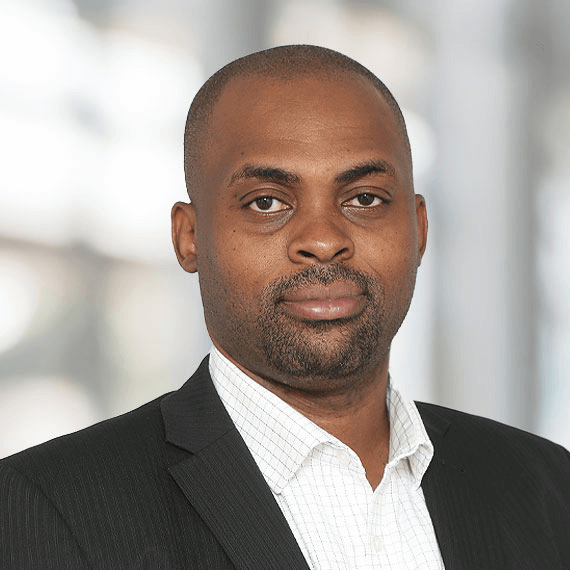

The company’s External Relations Manager Sauda Simba, said in an exclusive interview that, the task force team formed to carry out the assessment works is going on with the modalities put in place to ensure that, the work of updating individual information is completed within the stipulated timelines.

She told The BusinessWiz when contacted for comment yesterday that, “there are still some challenges the company is facing adding that her company is however undertaking strategic legal measures as to address them while engaging with relocating people”.

She noted that, some untrustworthy individuals are cheating as they sneak into the project’s designated area and tend to erect an investment in form of houses with hopes to be compensated more, a factor that is controlled by officials from the district council.

The Kabanga Nickel mineral project in Tanzania which was discovered in Ngara district is the world’s largest developed grade nickel sulphide used to manufacture motor vehicle batteries that are easily converted into electricity systems.

The execution of the project was given a green light by Tanzania’s National Assembly on strict conditions after the signing agreement following reviews made on Mining Act of 2017.

According to newly introduced regulations as stipulated in the Act, “the firm was ordered not to start its operations immediately on conditions that it should have first together with other conditions build a smelting factory whose construction is going on in Kahama district, Shinyanga region”.

The two had agreed to build a hydrometallurgical processing technology that is more cost efficient with significantly lower environmental impact than a smelting firm.

But when contacted for more comments on the progress of the nickel project, the Tembo Nickel Country Director Benedict Busunzu said that, the company plans to adopt a hydrometallurgical, a newly discovered processing technology that is more cost efficient than smelting and has a significantly lower environmental impact.

Elaborating more, he noted that on completion of the processing plant would be used to purify mineral concentrates upon the start of production slated in 2025 with a view to ascertain its values correctly before exportation.

This is the largest development-ready nickel sulphide deposit in the world, unmatched in scale and grade with at least 30 years life of mine and further exploration upside.

Upon commencement of operations, the Kabanga Nickel project will produce class 1 battery grade nickel, cobalt, and copper refined metals in Tanzania. The cradle to gate operation will use hydromet technology that is significantly more cost-efficient than smelting.

The hydromet process will reduce the carbon footprint, minimize environmental impact, lower capital and production costs and contributes significantly to the economic growth of Tanzania.

When contacted by phone for additional information, the Minister for Minerals Doto Biteko, said that, the investment of the project has enabled the company be granted a 33 year land lease according to the law alongside mineral trading license by the government worth over US$ 1.2 billion paid in taxes and royalties on annual basis.

Commenting on the amended 2017 Mining Law, the minister clarified that, it was introduced with a number of new conditions on the way investors does business. The main features included a 16 percent free carried interest for the government and restrictions on the export of raw resources for beneficiation outside Tanzania.

“Our commitment is to create a ground for a win-win situation. We want Tanzanians to benefit from the country’s natural resources that we are blessed by God,” he stressed.

The company’s strategy is to sustainably deliver high-grade Class 1 nickel, copper and cobalt products to feed increasing demand from Electric Vehicle (EV) battery production.

The EV and energy storage markets are rapidly expanding as the world pushes to decarbonize, thereby accelerating the need for essential battery minerals such as class 1 nickel which is a key component in the manufacturing of battery cathodes.